Hello everyone,

I have a question regarding the manual control of a XH430-W210-R servo motor:

What does it mean if the red LED turns on (solid no blinking) when I enable the torque? How can I resolve the issue?

I have tried troubleshooting this issue myself but had no luck:

-

I am using the protocol version 2.0

-

I can successfully establish an RS485 connection to the servo motor. It also answers with the expected frames to all my requests.

-

I can even write commands to the RAM of the servo motor. For example I can enable the torque which results in the red LED being switched on by the servo motor. If I disable the torque the LED is switched back off. From what I can tell this tells me there is an error. But which one?

-

If I write for example the example write command (DYNAMIXEL Protocol 2.0 5.3.3) to the servo motor it does not move a bit. I suspect it is because of the error. Additionally if I read its current position it also hasn’t changed. I haven’t changed anything regarding the operating and drive modes but reading the corresponding registers gives me their initial default values from the manual.

-

The hardware error register is also 0 and the status packet of the goal position command is also without an error. It’s current position is 2056. With the goal position being 512 it should turn itself. Meaning I request a movement which is not stopped by the moving threshold.

-

When turning the servo on the LED blinks once. At the moment I don’t have a Robotis certified device for the USB connection from a windows machine to the servo motor.

-

I am using a STM Nucleo board attachted to an RS485 converter to communicate with the servo motor. But I think this is not the issue as I get the expected answers from the servo motor if I send a request fo it (as mentioned above).

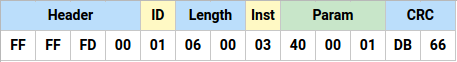

Lastly I can send you the commands I send to the servo motor and the resulting answer from the servo motor:

Torque on:

PC: <0xFF><0xFF><0xFD><0x00><0x01><0x07><0x00><0x03><0x40><0x00><0x00><0x01><0x41><0x5d> (LED turns on)

Dynamixel: <0xFF> <0xFF> <0xFD> <0x00> <0x01> <0x04> <0x00> <0x55> <0x00> <0xA1> <0x0C>

Hardware Error Status:

PC: <0xFF><0xFF><0xFD><0x00><0x01><0x07><0x00><0x02><0x46><0x00><0x01><0x00><0x3c><0xa3>

Dynamixel: <0xFF> <0xFF> <0xFD> <0x00> <0x01> <0x05> <0x00> <0x55> <0x00> <0x00> <0x53> <0x21>

From what I can tell there are no error transmitted in the servos answers.

Thank you for your help!