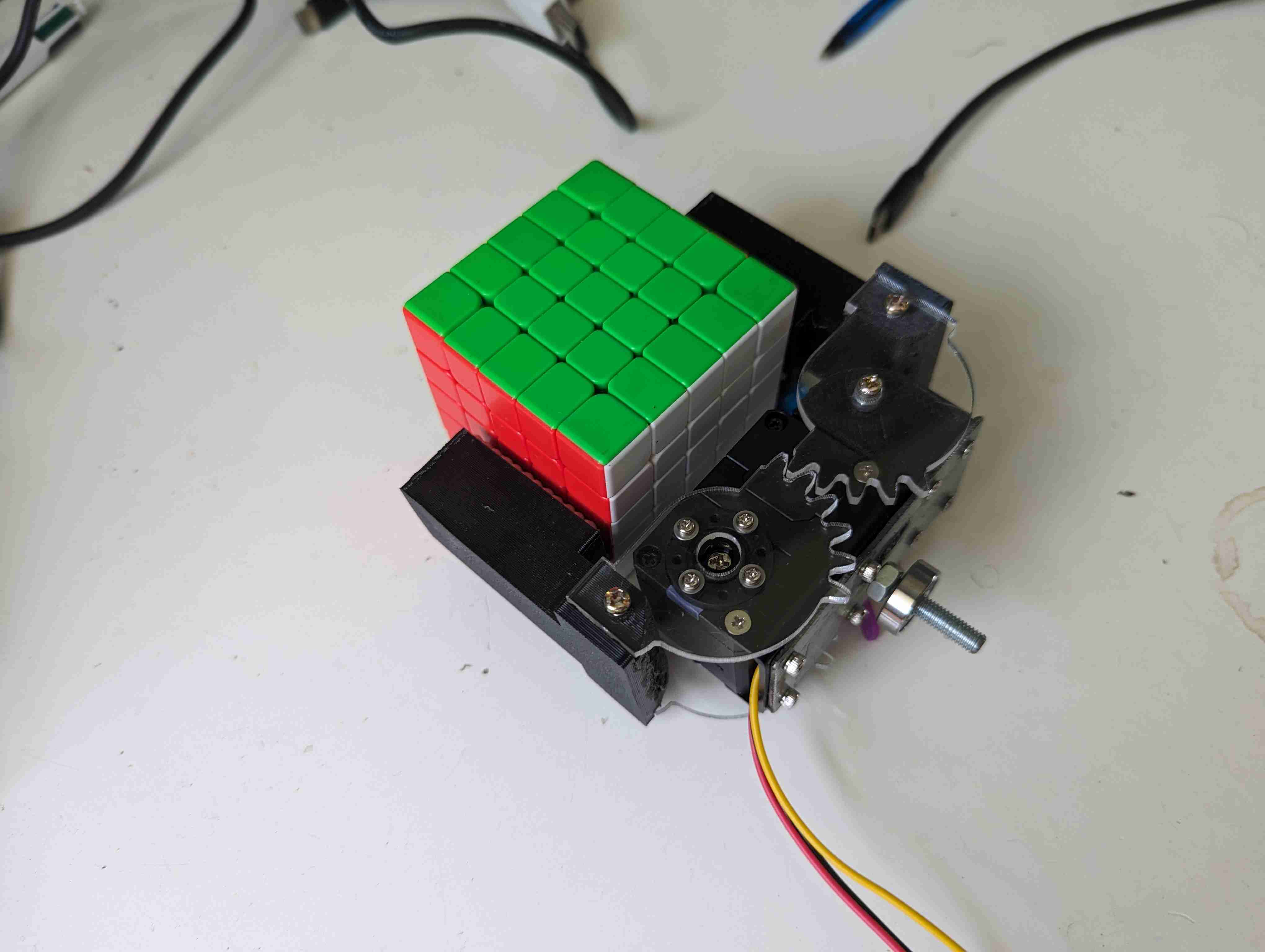

I am developing the next generation of my 5x5x5 Rubik’s cube solving robot fro an up coming competition in middle of 2024. see my original version here https://www.youtube.com/watch?v=sD4bG8hPYLQ

I am wanting to improve the time taken for the robot to solve the cube. You will notice the hobby servos that I am using to open and close the grippers move much slower than the stepper motors I am using to move the grippers.

I am replacing the 3 hobby servos with 3 DYNAMIXEL XC430-W150-T as they only have a 150 teeth reduction which means they are very fast but have low torque.

The gripper job is to hold the cube so I need to design to produce the max friction force with the limited torque.

I have been developing the design for a few iterations and here’s the latest.

The force perpendicular to the radius of rotation (motor axle) = torque / distance from axis of rotation). So the closer I can get the cube to the motor the more the force perpendicular to the radius. But the cube needs to be far away enough that when other gripper are turning faces of the cube they don’t collide.

Also the friction for is proportional to the force perpendicular to the cube face not eh radius of the rotation. So the more I can place the motor axle directly under the cube face the more efficient I will be with the limited torque. But I still have to make sure it doesn’t collide with the other grippers moving the other faces of the cube.

There’s no point in making a great performing design if it is too hard for me to manufacture in my garage.

I am pretty have with my latest iteration and I think it will be very close to final design. There is likely to be a few small changes once I actually start to use it to solve cubes and discover all the teething issues.

If people are interested I an post a little more about the over design of the whole robot.

3 Likes

Down under, Summer must be approaching and the kids are about to be out of school! Very cool project! My teen grandson is very impressed and wants me to build one for him (of course) but I only have XL-330 so probably not enough torque?

Access to 3-D printer and laser cutter are also a must?

1 Like

This looks pretty cool. I haven’t seen an automated solution for solving 5x cubes before. I’d be very interested in hearing more about this new revision!

@roboteer

Your right that the XL-330 is unlikely to have enough torque to hold a Cube or turn the faces. The XL-330 series are physically smaller at run at a lower voltage of 5v compared to XL-430 or XC-430 which are a bit larger and run at a higher voltage of 12v.

It is always a case of trying to balance: size, power and price. I chose the XC-430 because they have great size and power without being too expensive.

Access to 3-D printer and laser cutter are also a must?

Yes in order to develop working robots you need to be able to rapidly iterate the development cycle: design, build, test, improve.

I did find the combo of a laser cutter and 3D printer to be the best. Laser cutter is very fast and acrylic has very high strength to weight ratio but is only 2D. 3D printer is 3D but is slow if trying to print larger parts.

Over a few posts I will explain the robot and some of my design choices, this post I will talk about the motors.

There is a total of 6 motors on the robot ATM, I am using 3 DYNAMIXEL XC430-W150-T and 3 Stepper motors 17HS19-2004S1.

The 3 dynamixels motors are used to open and close the grippers that hold the cube and the faces of the cube. The 3 stepper motor move the grippers to grab different parts of the cube as well as move the grippers to turn faces.

I choose the dynamixels for the gripper operation because they need to be mounted internally in the grippers so they must be compact, light and powerful

I choose steppers for the moving of the grippers to turn the faces because they need to be super accurate so that the faces align perfectly so not to cause jamming or excess friction.

Stepper motors vs Servo motors.

Stepper motor are very inefficient (high electrical power input for low mechanical power output). They are large and super heavy. They require a real time processor to create the signal train to control them. Stepper motors can operate super accurately and super low speeds.

Dynamixel Servo motors have much higher efficiency and are compact, light and easy to control from high level API. All servo motors have trouble moving at low speeds at stopping super accurately.

If I want to replace the steppers with Dynamixels I would likely need to use one of the high performance models which will blow my budget.

2 Likes