DYNAMIXELs can be daisy-chained together for simplified control and wiring, a feature many of you are familiar with. But, integrating servos with mixed operating voltages into a single daisy chain presents extra challenges. I wanted to shed some light on this subject and provide you with a recommended approach to tackle this task effectively.

Caution:

Be careful when attempting to combine DYNAMIXELs with different voltages in a daisy chain:

A mistake in wiring in a setup like this can result in irreparable damage to your actuators. Additionally, unsafe wiring can pose a safety hazard both due to shock risk, or a possibility of fire. While outcomes that severe can be unlikely, it’s still important to keep that in mind as we move forward.

With that out of the way, I also want to share a bit about the “why” before getting to the “how”:

In almost any complex robotic design, you’re going to end up needing at least a few different sizes and shapes of actuators, to drive the different axes of motion. For DYNAMIXEL actuators in specific some combinations, like mixing different XM430 and XM540 servos, can be easily implemented through DYNAMIXEL’s basic daisy chaining functionality.

However, sometimes you might need to use (for example) XL430 and XL330 servos for a small desktop robot design, but XL330 servos can’t operate on the 12v needed for the XL430 to function. While it’s possible to solve this by creating two independent DYNAMIXEL chains and controlling the servos separately from each other, that introduces complexity in controller setup, as well as making it more difficult to control both actuators in coordination. In cases like this, setting up a mixed voltage daisy chain is the best solution to the problem.

Now, the actual explanation:

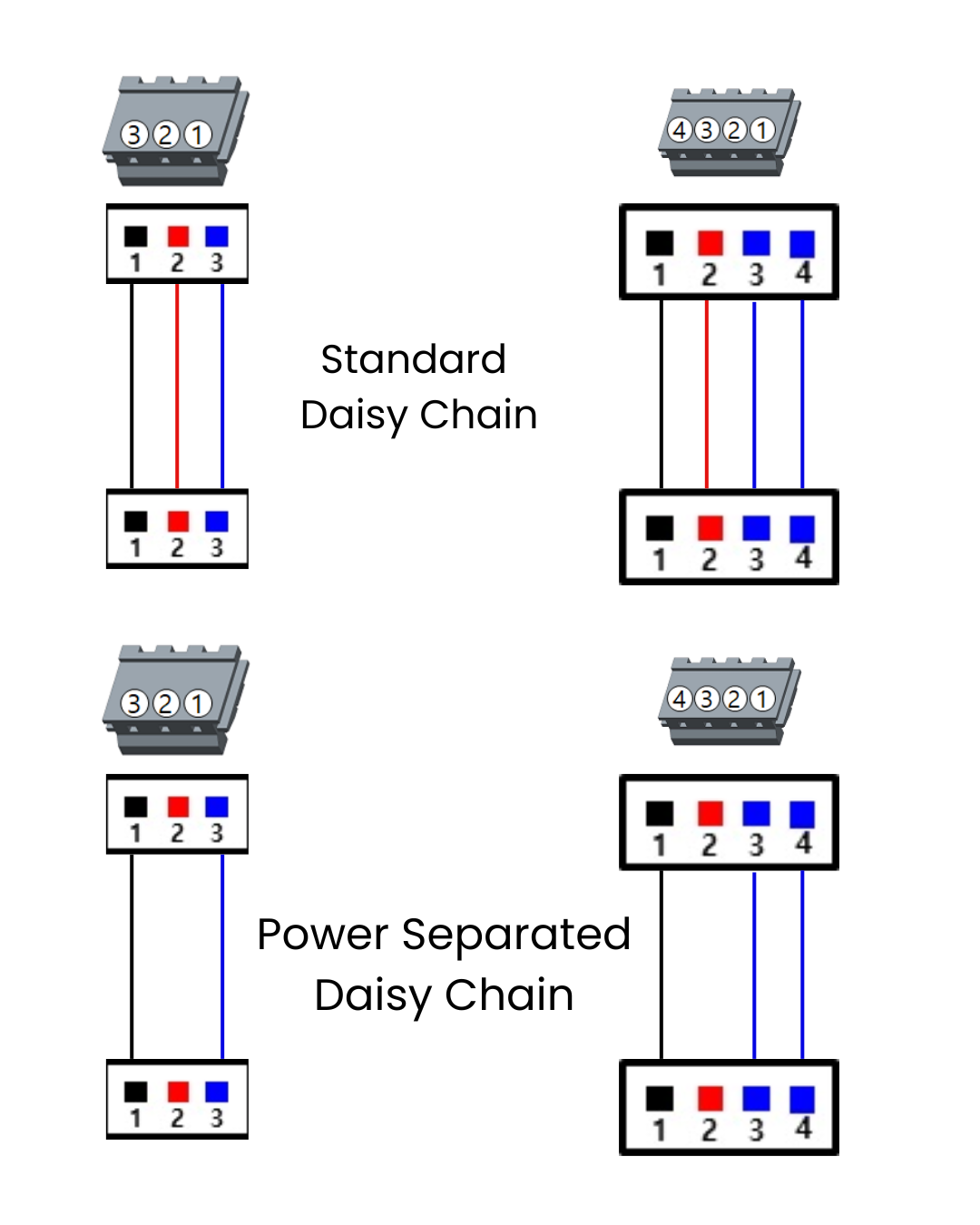

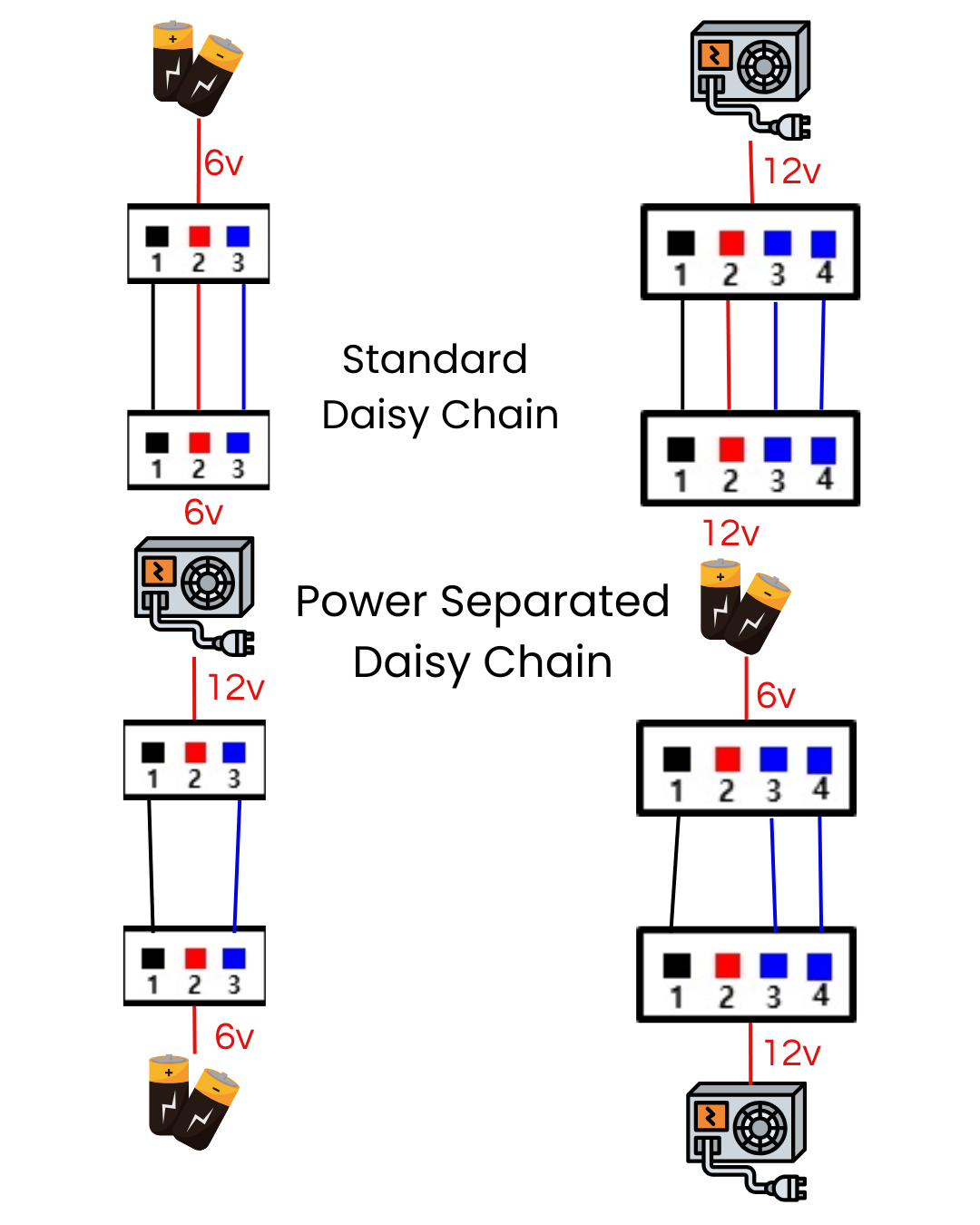

In short, a mixed voltage daisy chain is a DYNAMIXEL daisy chain that includes two separate power supply circuits, to supply different servo models with their required input voltage. To set up a system like this, you’ll need to separate the two power supply sections by cutting the voltage line between the sections with different voltage actuators.

The line that you need to cut will differ depending on the communications protocol for the actuator in question, but generally speaking, it will be the middle wire in the DYNAMIXEL connector. It is crucial not to cut the data lines as this should be continuous across all servos in the chain for proper communication.

After cutting the voltage wire, you can then connect two different power supplies to either ends of the separated power circuits, ensuring each actuator receives the appropriate voltage. Be careful when connecting the power supply to any terminal blocks or jumper wires, as reversing the polarity can cause damage to the servos. Always ensure the power supply voltage matches the requirements of each specific actuator in the connected chain.

Lastly, while implementing the mixed operating voltage daisy chain, you should be mindful of the individual current requirements for each DYNAMIXEL series. It’s crucial that your power supply can deliver enough current for all connected actuators, especially under maximum load conditions.

Although setting up a mixed operating voltage daisy chain can require more upfront planning and work, the benefits it brings in terms of flexibility and seamless control can make it well worth the effort. As always, if you have questions or need further help, don’t hesitate to reach out. Our team at ROBOTIS is always here to support your robotics journey.

Remember, safety first and happy building!