Use the following template to help create your post:

-

State the model of servo you are using.

MX-64 -

Add (or create) Tags to your post with the specific model of your product.

-

Describe your control environment. This includes the controller or interface, computer and OS, and any power source you are using

I am using Labview -

Specify the operating mode you are using, for applicable models.

pwm mode -

Specify and link any manuals or resources you have used related to your inquiry.

Emanual -

Include pictures if possible. This can help our members see how wires are connected, how hardware is installed, or to identify other possible issues.

My question,

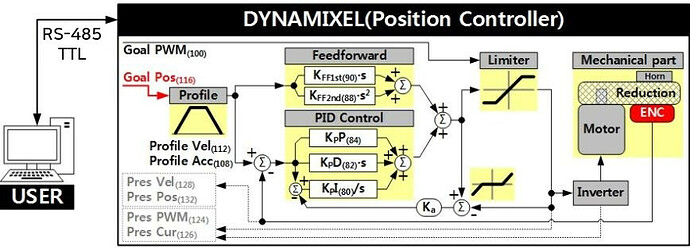

I read the control algrithm of Mx-64 from emanual, and use wizard2.0 to test it in position mode

- I check the position KP gain is 850, but I dont know what is the delta (target-current) if delta*kp= pwm. the delta is target pos-current pos or target degree- current degree

- I using PWM mode and create my own KP controller, I compare my controller and dynamxiel position mode KP controller, dynamixel KP controller is more precisive and stable no vibration.

in my understand, there are should be the same, so what is the differnece between my own KP controller and dynamxiel KP controller.