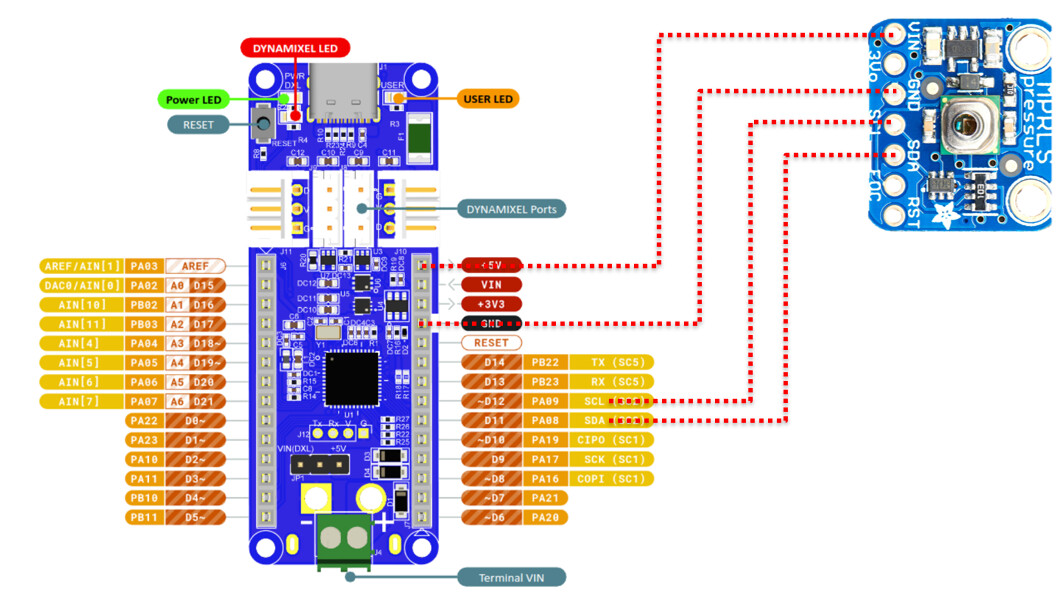

Hi @roboteer Many thanks for your clear explanation of the serial port configuration. It entirely solved my confusion on this. I also modified my code as you suggested. However, I still have this issue.

My code is like below:

//Adafruit section

#include <Wire.h>

#include “Adafruit_MPRLS.h”

#define RESET_PIN -1 // set to any GPIO pin # to hard-reset on begin()

#define EOC_PIN -1 // set to any GPIO pin to read end-of-conversion by pin

Adafruit_MPRLS mpr = Adafruit_MPRLS(RESET_PIN, EOC_PIN);

#include <RC100.h>

RC100 Controller;

uint16_t RcvData = 0;

#include <Dynamixel2Arduino.h>

// Please modify it to suit your hardware.

#if defined(ARDUINO_AVR_UNO) || defined(ARDUINO_AVR_MEGA2560) // When using DynamixelShield

#include <SoftwareSerial.h>

SoftwareSerial soft_serial(7, 8); // DYNAMIXELShield UART RX/TX

#define DXL_SERIAL Serial

#define DEBUG_SERIAL soft_serial

const int DXL_DIR_PIN = 2; // DYNAMIXEL Shield DIR PIN

#elif defined(ARDUINO_OpenRB) // When using OpenRB-150

//OpenRB does not require the DIR control pin.

#define DXL_SERIAL Serial1

#define DEBUG_SERIAL Serial

// const int DXL_DIR_PIN = -1;

const int DXL_DIR_PIN = 5;

#else // Other boards when using DynamixelShield

#define DXL_SERIAL Serial1

#define DEBUG_SERIAL Serial

const int DXL_DIR_PIN = 2; // DYNAMIXEL Shield DIR PIN

#endif

Dynamixel2Arduino dxl(DXL_SERIAL, DXL_DIR_PIN);

using namespace ControlTableItem;

const float DXL_PROTOCOL_VERSION = 2.0;

const uint8_t gr_ID = 1;

const uint8_t rt_ID = 2;

const uint8_t df_ID = 3;

const uint8_t fd_ID = 4;

double gr_CP, gr_DP, gr_initial, rt_CP, rt_DP, rt_initial, df_CP, df_DP, df_initial, fd_CP, fd_DP, fd_initial;

void setup(){

//Adafruit section

Serial.begin(115200);

Serial.println(“MPRLS Simple Test”);

if (! mpr.begin()) {

Serial.println(“Failed to communicate with MPRLS sensor, check wiring?”);

while (1) {

delay(10);

}

}

Serial.println(“Found MPRLS sensor”);

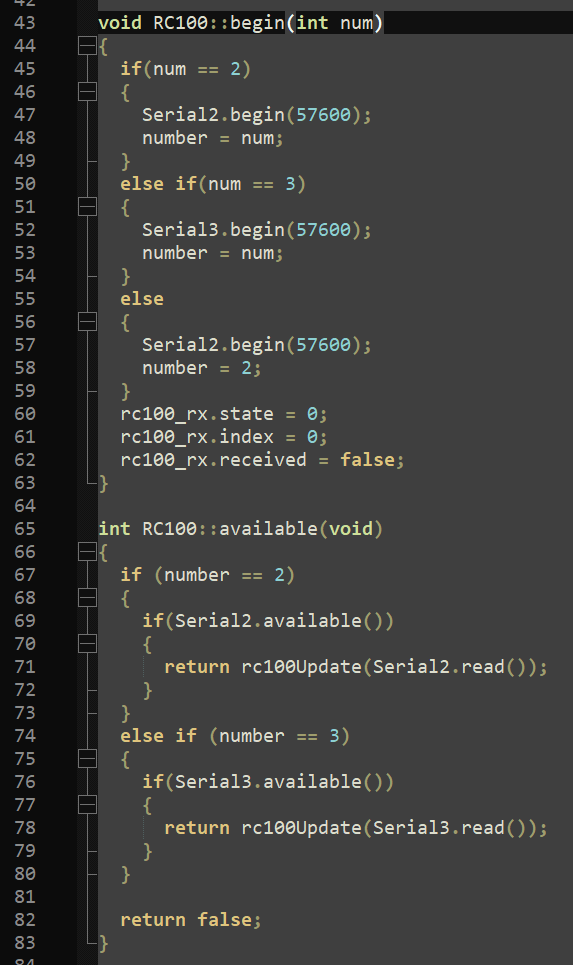

Controller.begin(2);

// Set Port baudrate to 57600bps. This has to match with DYNAMIXEL baudrate.

dxl.begin(57600);

dxl.setPortProtocolVersion(DXL_PROTOCOL_VERSION);

// Get DYNAMIXEL information

dxl.ping(gr_ID);

dxl.ping(rt_ID);

dxl.ping(df_ID);

dxl.ping(fd_ID);

// Turn off torque when configuring items in EEPROM area, set PWM mode

dxl.torqueOff(gr_ID);

dxl.setOperatingMode(gr_ID, OP_EXTENDED_POSITION);

dxl.torqueOn(gr_ID);

dxl.writeControlTableItem(PROFILE_VELOCITY, gr_ID, 50);

dxl.torqueOff(rt_ID);

dxl.setOperatingMode(rt_ID, OP_POSITION);//limit rotation angle

dxl.torqueOn(rt_ID);

dxl.writeControlTableItem(PROFILE_VELOCITY, rt_ID, 50);

dxl.torqueOff(df_ID);

dxl.setOperatingMode(df_ID, OP_EXTENDED_POSITION);

dxl.torqueOn(df_ID);

dxl.writeControlTableItem(PROFILE_VELOCITY, df_ID, 50);

dxl.torqueOff(fd_ID);

dxl.setOperatingMode(fd_ID, OP_EXTENDED_POSITION);

dxl.torqueOn(fd_ID);

dxl.writeControlTableItem(PROFILE_VELOCITY, fd_ID, 50);

}

void loop(){

// MPRLS section

float pressure_hPa = mpr.readPressure();

Serial.print("Pressure (hPa): "); Serial.println(pressure_hPa/10);

delay(50);

RcvData = 0;

if (Controller.available()){

RcvData = Controller.readData();

}

if(RcvData == (RC100_BTN_L)){

gr_CP = dxl.getPresentPosition(gr_ID, UNIT_DEGREE);

gr_DP = gr_CP + 5;

dxl.setGoalPosition(gr_ID, gr_DP, UNIT_DEGREE);

}

if(RcvData == (RC100_BTN_R)){

gr_CP = dxl.getPresentPosition(gr_ID, UNIT_DEGREE);

gr_DP = gr_CP - 5;

dxl.setGoalPosition(gr_ID, gr_DP, UNIT_DEGREE);

}

if(RcvData == (RC100_BTN_1)){

df_CP = dxl.getPresentPosition(df_ID, UNIT_DEGREE);

df_DP = df_CP + 5;

dxl.setGoalPosition(df_ID, df_DP, UNIT_DEGREE);

}

if(RcvData == (RC100_BTN_3)){

df_CP = dxl.getPresentPosition(df_ID, UNIT_DEGREE);

df_DP = df_CP - 5;

dxl.setGoalPosition(df_ID, df_DP, UNIT_DEGREE);

}

}

The baud rates of these actuators are all set as 57600.

-

When I comment the Adafruit section in both void setup() and void loop(), my RC100 controller can control all actuators successfully via BT210 assembled on the OpenRB150;

-

When I comment the Adafruit section in only the void loop(), it still works but the serial port displays nothing;

-

When I keep the Adafruit section in both void setup() and void loop(), the actuators can not be controlled via BT210 but the serial port displays sensor data successfully;

It looks like something conflicts between the two, but not the serial port setup? What do you think about this?