@cbnu167

This is a more detailed procedure using simultaneous equations (it is less rigorous than statistical regression), nonetheless it will do the job for you.

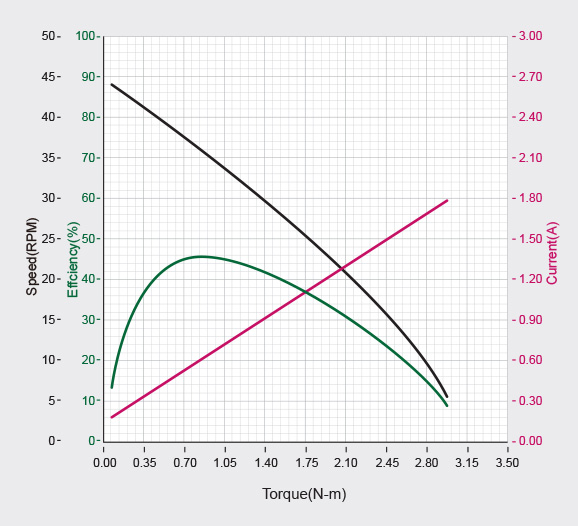

Fitting XM430-W350 Torque (T) vs Current (C) to a Linear Function from Performance Graph at (XM430-W350-T/R).

As the T vs C graph looks “linear”, we’ll try to fit a Linear Function to it, so:

T = a * C + b Eq. (1) - where Unknown Parameters are a and b

The “curve-fitting” procedure is listed below:

-

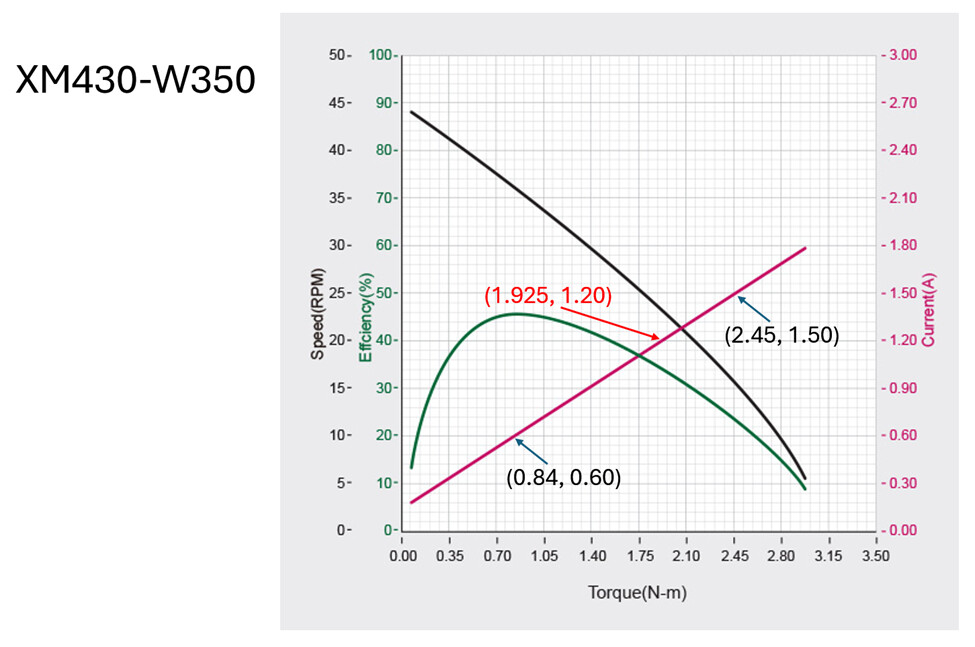

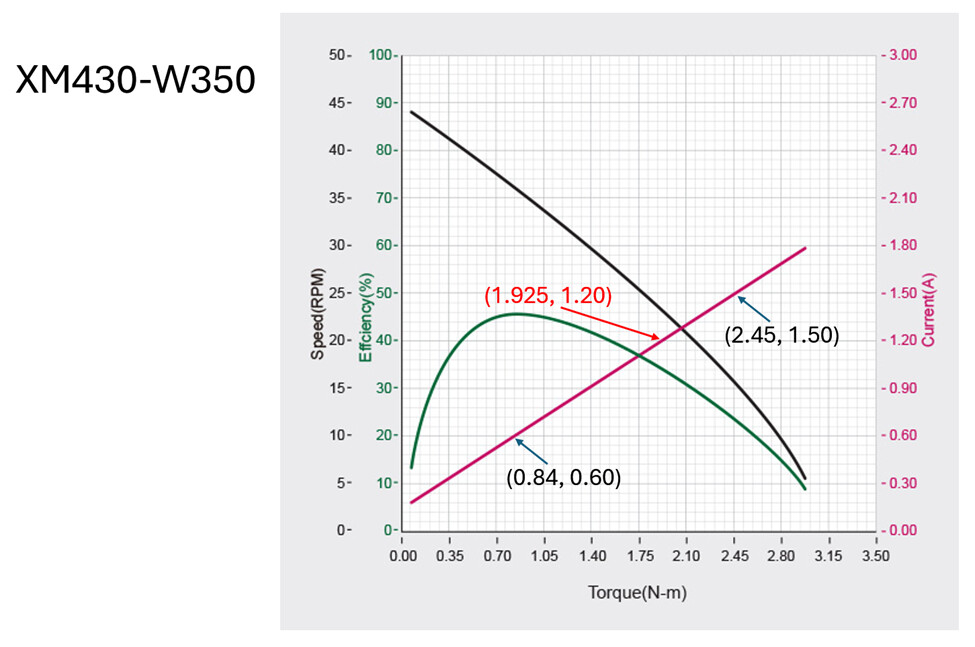

Find (T,C) coordinates for 3 points that are on the T/C Graph. I chose (0.84, 0.60), (2.45, 1.50) and (1.925, 1.20). We’ll use the 3rd data point (1.925, 1.20) to check our function fitting results.

-

To get rid of Parameter b, apply the first two Data Points to Eq. (1):

- Using (0.84, 0.60), Eq. (1)] yields 0.84 = a * 0.60 + b Eq. (2)

- Using (2.45, 1.50), Eq. (1)] yields 2.45 = a * 1.50 + b Eq. (3)

-

Determination of Parameter a:

- [Eq. (2) – Eq. (1)] yields 1.61 = a *0.91 therefore a = 1.769

-

Determination of Parameter b with Eq. (2):

- Eq. (2) is solved for b = 0.84 – (1.769 * 0.60) = -0.2214, so b = -0.2214

-

So, the T/C Performance Graph can be analytically represented as Eq. (4):

T = 1.769 * C – 0.2214

- Where C is in Amperes (A) and T is in Newton-Meter (N-m)

-

Checking the results with 3rd Data Point (1.925, 1.2):

- Using C=1.2 in Eq. (4) yields T = 1.769 * 1.2 – 0.2214 = 1.9 (pretty close to 1.925 as shown on the graph).

Application in C++/Python programming

According to the XM430-W350 Control Table, at run-time, you can use DXL SDK to read in Present Current (PC126) at Address 126

(XM430-W350-T/R).

This PC126 number is supposed to be a signed 16-bit integer between (- Goal_Current) and (+Goal_Current), to be found at Address 102. By default, this range is between (-1193) and (+1193) – in decimal, and its unit value is 2.69 mA.

In ROBOTIS software/firmware, negative integers use the 2-complement binary format for a 16-bit integer, however Python/C++ does not know that in advance, so it would just print out the 2-complement integer as is (between 0 and 65535) – to the confusion of many users.

So, as a programmer for your Python/C++ code, you need to do some checking before converting PC126 into a C value that you can use with your Eq. 4 from above:

// Assuming 16-bit 2-complement integers - pseudo code

if (PC126 > 32767) // when NEGATIVE VALUES for PC126

PC126 = (65536 – PC126) * (-1); // this is a signed decimal integer

else // when POSITIVE VALUES for PC126

PC126 = PC126;

// Computing C in A, using abs(PC126)

C = abs(PC126) * 2.69 / 1000.0; // in A

T = 1.769 * C – 0.2214; // in N-m