There has been sometimes that it has been hard to communicate with this type of smart motors, I don’t always remember the set ID or even the last configured baud rate for serial communication, or even the simple task of changing a single parameter requires to write a custom program to change that value to that specific motor, for that reason I decided to start building a handheld device that will make this kind of tasks easier and faster.

A simple UI in a TFT LCD will let configure these motors in a few steps, the project is going to integrate electronics used in other of my projects to make this development easier and faster, hoping to have feedback from the robotics community who have work with this kind of motors by letting me know the best path to follow.

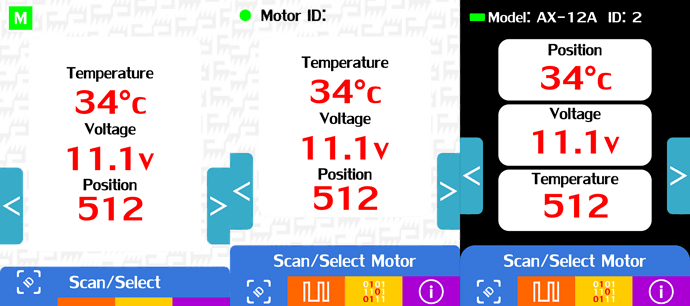

In this first step I will have a first approach for the graphical interface, here are some ideas that I have tried, and the most recent one.

Wiring the test hardware

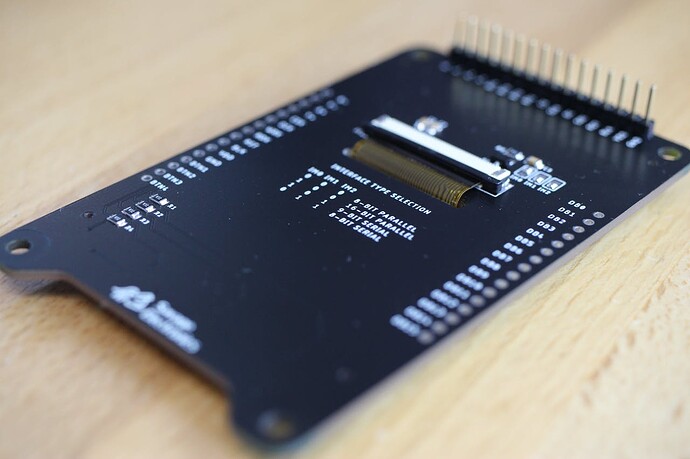

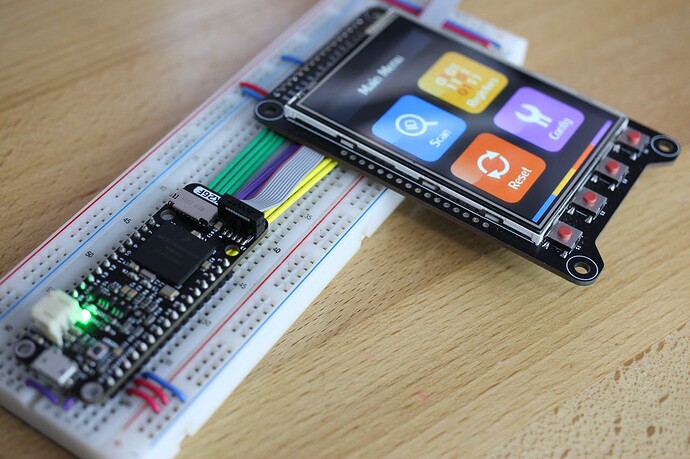

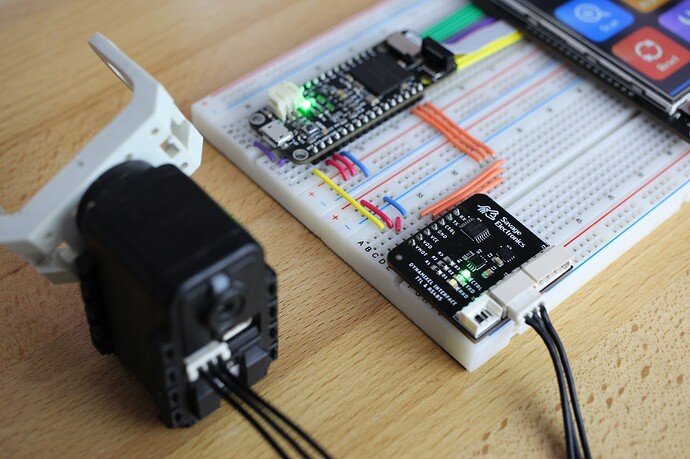

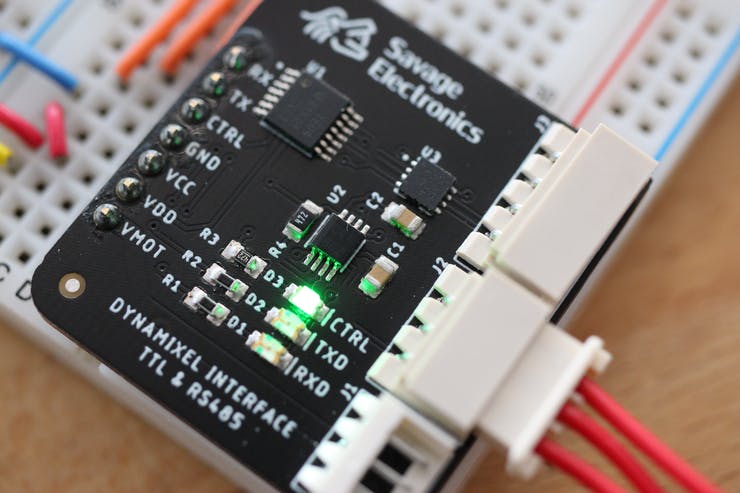

I will be using an ST7789V controller 2.8 inch TFT LCD for this project as I think it is a good size for the data it will work with. I will also be using the MK26F microcontroller that I have in a Feather format and a Dynamixel interface board for communication with the motors.

So it needs to be all wired, connecting the SPI, ADCs, and GPIOs from the feather board to the TFT LCD Breakout board.

And also needs to be wired the Dynamixel interface board, I am using a new interface board to test correctly this project in the future.

Graphics for the interface

I have added some interesting things to the graphics for a more fluid and friendly interface as movement on the main menu icons, as shown in the next picture.

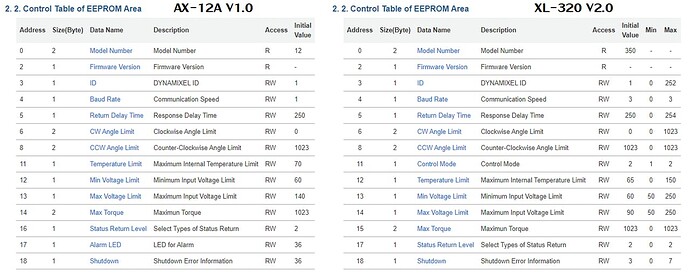

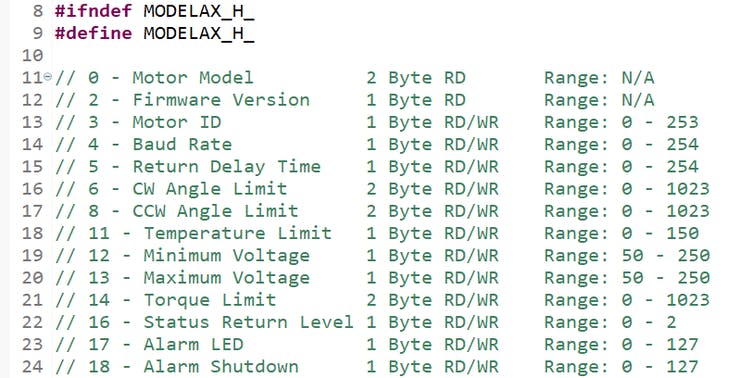

I have noticed that there are a lot of Dynamixel motors, the classic AX-12A use the protocol V1.0 but the newer one uses the V2.0 and also they change some registers address making this whole idea a bit difficult, I am still thinking how many motor models this device will support, as a first step I will make the firmware ready for the AX-12A and the XL-320 as I think are most popular one and also the cheapest.

The first step is to port the Dynamixel library for Arduino that I wrote many years ago to my microcontroller and then also update the library to be compatible with the V2.0 Dynamixel protocol.

Registers in EEPROM Area

So there are some slight differences between registers address and all of this have to take in count when showing the info the configurator, so I have started to register this tables in a model file and maybe would be updated in a more compressible file in the future.

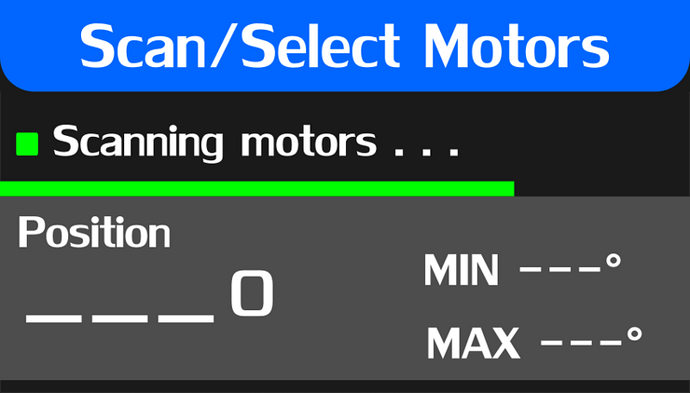

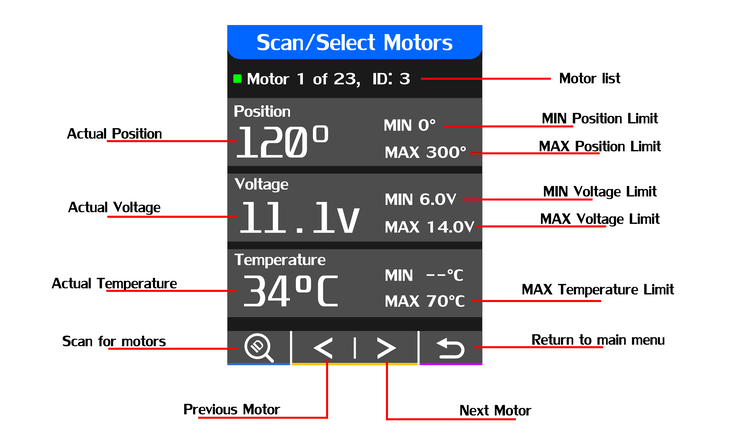

Motor scanning and selection menu

In order to test or modify the motor register, we need to scan and select the connected motors, for this task I have created a short function that Ping the bus and waits for each motor ID, and adds it to the motor list at a given baud rate and protocol.

After the motor scanning, it’s useful to know certain values of the motor so I decided to read these and display them in the same window with the capability to scroll the motor list and at the same time select the motor of interest.

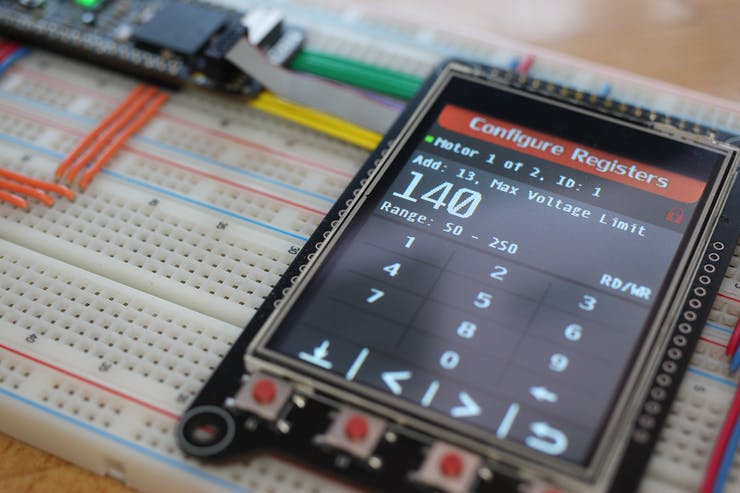

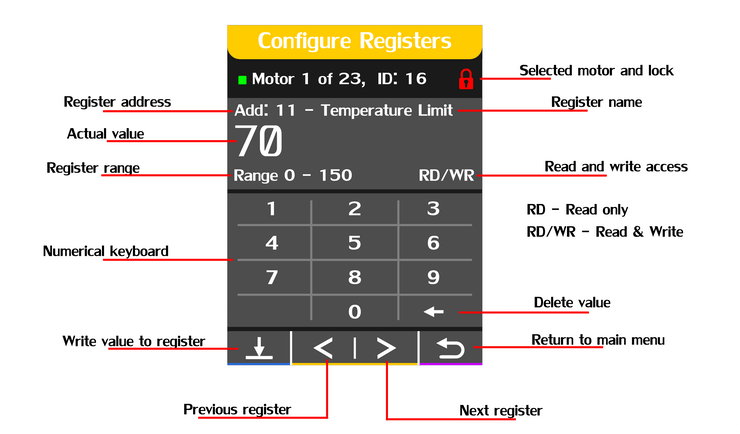

Configure Registers Window

In this window will be able to read and write directly to register of the selected motor in the previous windows, it will be accessible to both the EEPROM and RAM registers in order to properly test the written values, limits, or alarms.

The new values will be written on a numerical touchscreen keyboard.

This window also shows if the EEPROM data is write-protected, in order to write the torque of the motor should be disabled, this can be done by writing a 0 to the Torque Enable register in address 24.

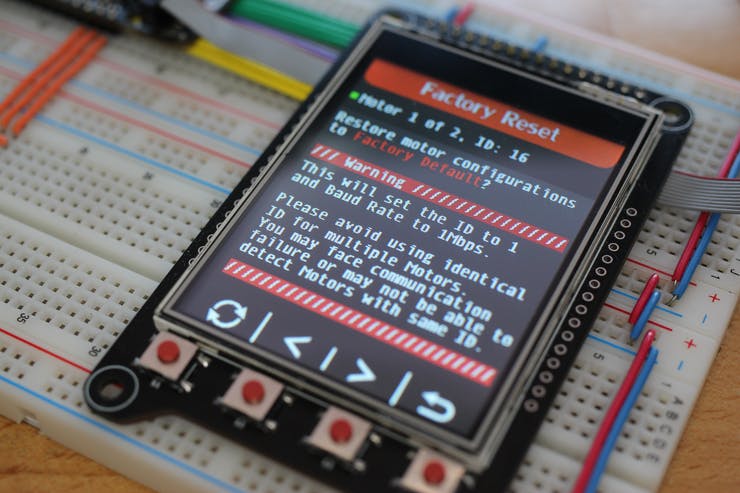

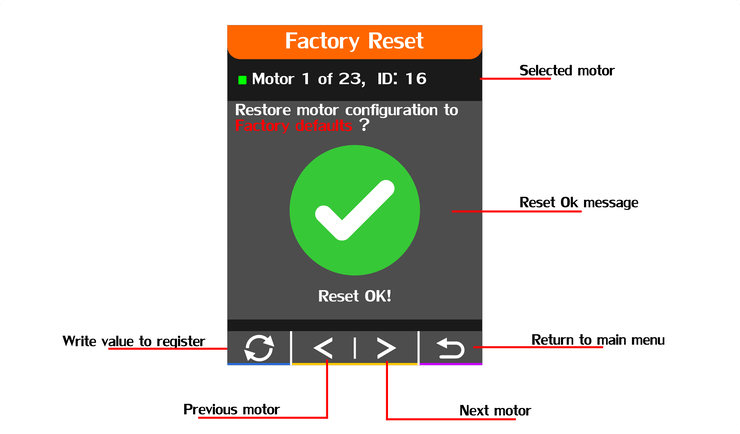

Factory Reset Window

The factory reset window is a simple but very efficient way to restore motor parameters to factory defaults with a press of a button.

This option will perform a reset function on the Dynamixel instructions set, so all it been handled by the motor itself, the motor list its also accessible from this window but it has to be in consideration that motors should not have the same ID as it can cause errors in the communication.

When a reset has finished successfully this window will also inform and will let you continue with the reset operations that you may need for other motors.

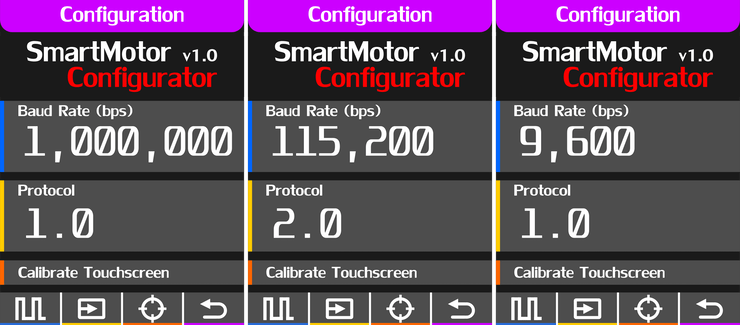

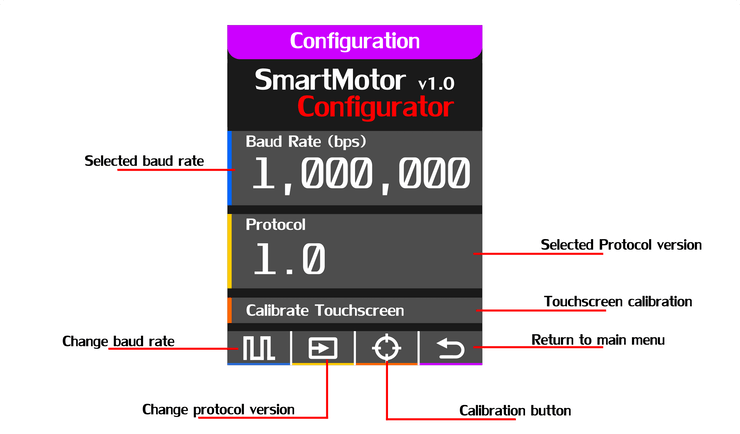

Configuration Window

The configuration windows allow to change the Baud rate speed, the Dynamixel protocol and perform a touchscreen calibration if needed.

As you have already noticed the touchscreen calibration options are accessible with the tact switches in case that the touchscreen values have changed over time, the only action that needs the touchscreen is the keyboard on the register configuration window.

Adding the Dynamixel Interface TTL & RS-485

In order to manage the most number of Dynamixel motors I will add the TTL and RS-485 Interface, also will integrate the 3 connectors needed for these motors.