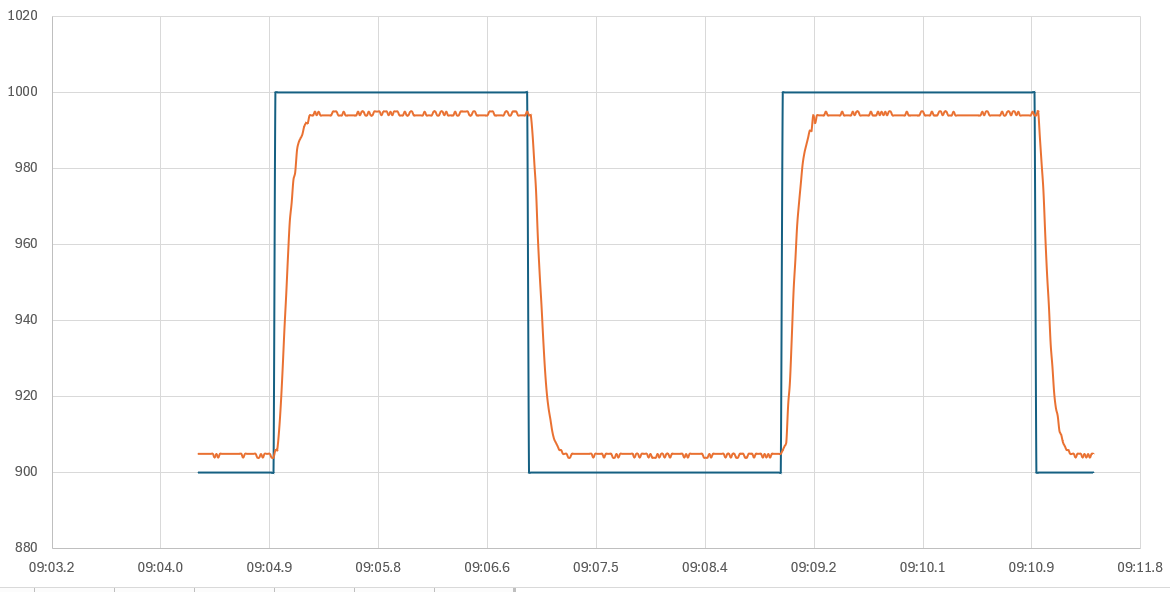

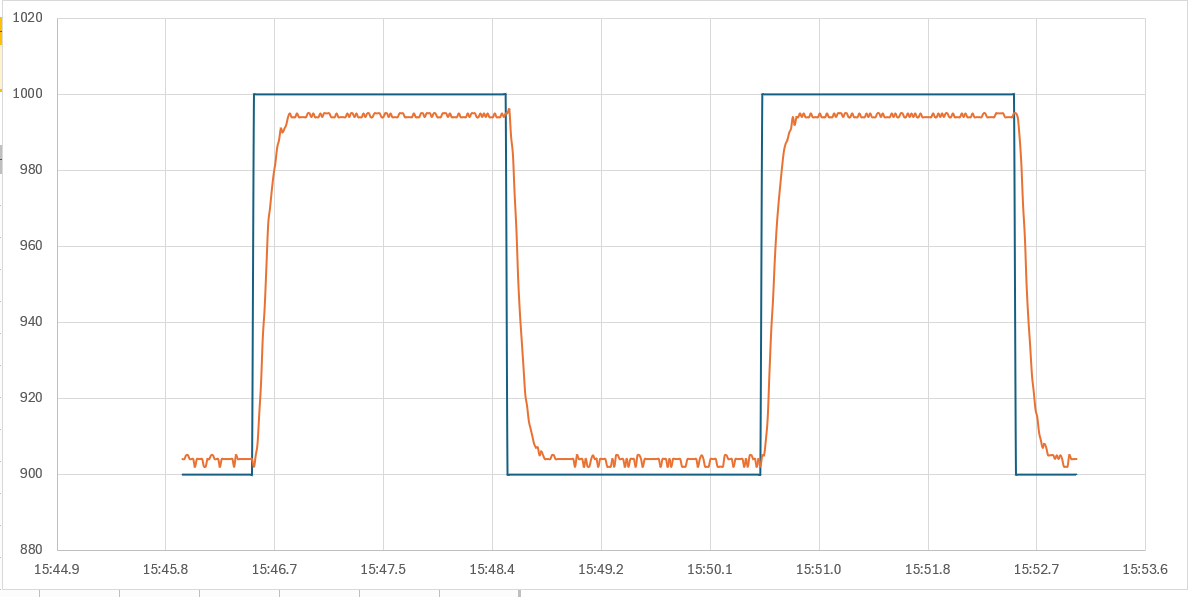

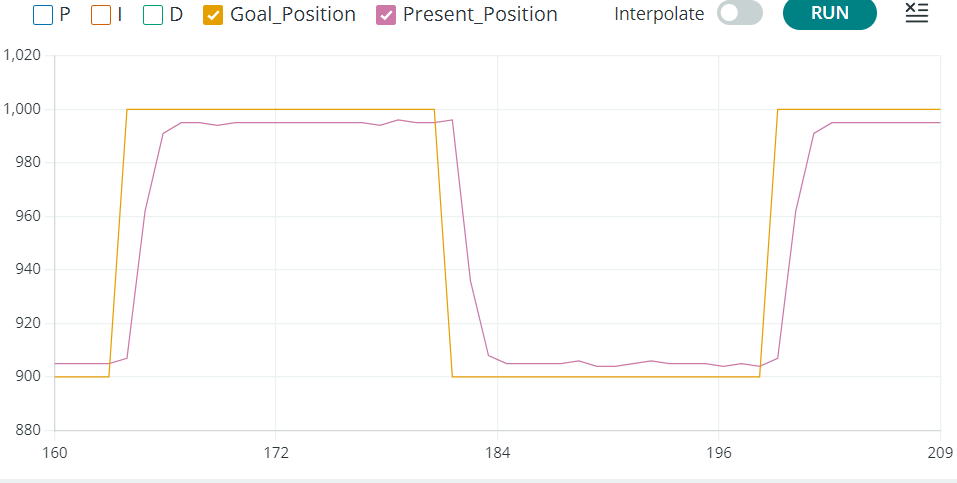

Hello everyone! I’m new to control system and Robotis product. So, I have a problem related to changing the PID value of the XL-320. So, I use system identification in Matlab to obtain the transfer function (using the goal and present position detected by the XL-320), then tune the Kp, Ki and Kd value to get the desired response of the system. Then, I try to put those (Kp, Ki, Kd) values to the Dynamixel XL-320 via Dynamixel Wizard 2 + OpenRB-150 and also try it in the Dynamixel+Arduino Uno, but both of the final response doesn’t change at all . Here attach the code that I used in the Arduino. Does anyone know what my problem is and how to solve this problem? Thank you in advance!

Regards,

Eka

/*******************************************************************************

* Copyright 2016 ROBOTIS CO., LTD.

*

* Licensed under the Apache License, Version 2.0 (the "License");

* you may not use this file except in compliance with the License.

* You may obtain a copy of the License at

*

* http://www.apache.org/licenses/LICENSE-2.0

*

* Unless required by applicable law or agreed to in writing, software

* distributed under the License is distributed on an "AS IS" BASIS,

* WITHOUT WARRANTIES OR CONDITIONS OF ANY KIND, either express or implied.

* See the License for the specific language governing permissions and

* limitations under the License.

*******************************************************************************/

/** Please refer to each DYNAMIXEL eManual(http://emanual.robotis.com) for supported Operating Mode

* Operating Mode

* 1. OP_POSITION (Position Control Mode in protocol2.0, Joint Mode in protocol1.0)

* 2. OP_VELOCITY (Velocity Control Mode in protocol2.0, Speed Mode in protocol1.0)

* 3. OP_PWM (PWM Control Mode in protocol2.0)

* 4. OP_EXTENDED_POSITION (Extended Position Control Mode in protocol2.0, Multi-turn Mode(only MX series) in protocol1.0)

* 5. OP_CURRENT (Current Control Mode in protocol2.0, Torque Mode(only MX64,MX106) in protocol1.0)

* 6. OP_CURRENT_BASED_POSITION (Current Based Postion Control Mode in protocol2.0 (except MX28, XL430))

*/

#include <DynamixelShield.h>

#if defined(ARDUINO_AVR_UNO) || defined(ARDUINO_AVR_MEGA2560)

#include <SoftwareSerial.h>

SoftwareSerial soft_serial(7, 8); // DYNAMIXELShield UART RX/TX

#define DEBUG_SERIAL soft_serial

#elif defined(ARDUINO_SAM_DUE) || defined(ARDUINO_SAM_ZERO)

#define DEBUG_SERIAL SerialUSB

#else

#define DEBUG_SERIAL Serial

#endif

const uint8_t DXL_ID = 3;

const float DXL_PROTOCOL_VERSION = 2.0;

int32_t goal_position[2] = {900, 1000};

int8_t direction = 0;

unsigned long timer = 0;

// Position PID Gains

// Adjust these gains to tune the behavior of DYNAMIXEL

uint16_t position_p_gain = 1;

uint16_t position_i_gain = 20;

uint16_t position_d_gain = 0;

DynamixelShield dxl;

//This namespace is required to use Control table item names

using namespace ControlTableItem;

void setup() {

// put your setup code here, to run once:

// For Uno, Nano, Mini, and Mega, use UART port of DYNAMIXEL Shield to debug.

DEBUG_SERIAL.begin(115200);

// Set Port baudrate to 57600bps. This has to match with DYNAMIXEL baudrate.

dxl.begin(1000000);

// Set Port Protocol Version. This has to match with DYNAMIXEL protocol version.

dxl.setPortProtocolVersion(DXL_PROTOCOL_VERSION);

// Get DYNAMIXEL information

dxl.ping(DXL_ID);

// put your main code here, to run repeatedly:

// Position Control Mode in protocol2.0, Joint Mode in protocol1.0

// Turn off torque when configuring items in EEPROM area

dxl.torqueOff(DXL_ID);

dxl.setOperatingMode(DXL_ID, OP_POSITION);

dxl.torqueOn(DXL_ID);

// Set Position PID Gains

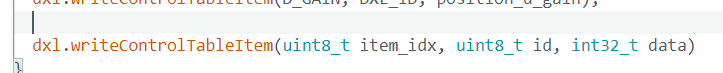

dxl.writeControlTableItem(POSITION_P_GAIN, DXL_ID, position_p_gain);

dxl.writeControlTableItem(POSITION_I_GAIN, DXL_ID, position_i_gain);

dxl.writeControlTableItem(POSITION_D_GAIN, DXL_ID, position_d_gain);

}

void loop(){

while(true) {

DEBUG_SERIAL.print("Goal_Position:");

DEBUG_SERIAL.print(dxl.readControlTableItem(GOAL_POSITION, DXL_ID));

DEBUG_SERIAL.print(",");

DEBUG_SERIAL.print("Present_Position:");

DEBUG_SERIAL.print(dxl.getPresentPosition(DXL_ID));

DEBUG_SERIAL.print(",");

DEBUG_SERIAL.println();

delay(10);

if (millis() - timer >= 2000) {

dxl.setGoalPosition(DXL_ID, goal_position[direction]);

timer = millis();

break;

}

}

if(direction >= 1) {

direction = 0;

} else {

direction = 1;

}

}