The Robotics Roundup is a weekly newspost going over some of the most exciting developments in robotics over the past week.

In today’s edition we have:

- Highly Dexterous Robot Hand Can Operate in the Dark — Just Like Us

- Rescue Robot will tackle nuclear power plant emergencies so humans don’t have to

- Engineers Go Neck and Neck with Nature

- Grain-surfing robot the latest innovation to set up home at the National Robotarium

- The Fastest Bot in the East

Highly Dexterous Robot Hand Can Operate in the Dark — Just Like Us

Dexterous Manipulation with Tactile Fingers

Researchers at Columbia Engineering have developed a highly dexterous robot hand that combines an advanced sense of touch with motor learning algorithms to achieve highly dexterous motion without vision sensors. The hand was able to perform a variety of difficult manipulation tasks without any visual feedback, using only advanced touch sensors embedded in the fingers. Without any need for visual object tracking the system is immune poor lighting, object occlusion, or other related issues that complicate other object manipulation frameworks. The researchers believe that this level of dexterity and the lack of visual requirements will open up entirely new applications for robotic manipulation in the real world, particularly in logistics, material handling, and advanced manufacturing in environments with poor visibility.

Rescue Robot will tackle nuclear power plant emergencies so humans don’t have to

A new remotely operated robotic platform designed for hazardous conditions has been successfully tested at the Sellafield nuclear site in Cumbria, UK. The robot, called the Rescue Robot, was designed and built by the Forth engineering firm and is intended to keep human workers safe during emergencies at nuclear power stations. Rescue Robot is built on a 1.6 ton JCB compactor excavator platform and is fitted with robust robotics systems, wireless technology, cameras and lights that can withstand hazardous conditions. Operation is completely tetherless, and the platform can be controlled from up to 150m away. The robot is equipped with a range of tools, including a 700bar rescue tool and a grapple hook to move obstructions. It can also tow a trailer to disperse sand for covering radiological hazards.

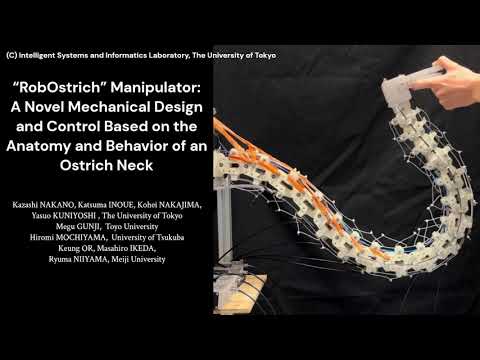

Engineers Go Neck and Neck with Nature

RobOstrich Manipulator: Robotic Manipulator based on the Anatomy and Behavior of an Ostrich Neck

Researchers at the University of Tokyo have developed a flexible robotic manipulator, inspired by the neck of an ostrich, capable of high dexterity and structural stability. Using 3D-printed vertebrae linked together with bearings, piano wire to simulate the muscular system, and rubber bands for tension, the manipulator named RobOstrich can complete complex movements, such as reaching for objects, using simple actuation patterns. Although it can only move in two dimensions at present, the team is working towards three-dimensional movement, with the manipulator potentially serving as the basis for a new generation of flexible robotic manipulators.

Grain-surfing robot the latest innovation to set up home at the National Robotarium

Agritech developer Crover has launched a burrowing robot that can “swim” through grain bulks to provide insight into the environmental conditions of grain crops when stored in sheds or silos. The t-shaped robot has in-built moisture and temperature sensors and uses two domed-shaped wheels to propel itself through grain or other material in a bulk stack, before feeding back analysis and data to a dashboard to give farmers a more accurate understanding of the grain’s condition. It is estimated that up to 30% of commodity grain is lost from the supply chain globally every year due to issues such as temperature and humidity impacting storage, and this robot can greatly improve farmer’s ability to monitor their storage and prevent these losses. The robot is being funded by Innovate UK, Scottish Enterprise and private funders, and Crover is a tenant of the National Robotarium, which provides access to state-of-the-art office and lab facilities and an ecosystem of collaborators, industry experts and academic teams.

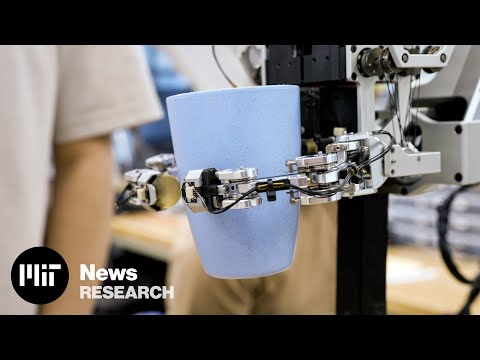

The Fastest Bot in the East

MIT engineers have developed a reflex-based gripper that adapts in the moment to reflexively roll, palm, or pinch an object to get a better hold, allowing for “last centimeter” adjustments. This is the first system of it’s type to incorporate reflexes into a robotic planning architecture. The robot demonstrated the flexibility of this grip implementation by clearing a cluttered shelf holding various household objects. This demonstration showed the robot quickly adapting its grasp to each object’s particular shape and characteristics. Out of 117 attempts, the gripper quickly and successfully picked and placed objects more than 90 percent of the time. The implications of this development point to future designs could give robots a more nimble, human-like touch and enable them to work in changing settings with high uncertainty, such as in households or workplaces.