Good morning

Am I on track for the mini?

Do you have an example of code to control the arm movement in the loop with the keyboard because I don’t know how to do it. I thank you in advance.

Sincerely

`<// **** Paramètres globaux pour les DXL *********

#include <Dynamixel2Arduino.h>

#define DXL_SERIAL Serial1

#define DEBUG_SERIAL Serial

// **** Global Parameters for DXLs *********

const uint8_t BROADCAST_ID = 254;

const uint8_t DXL_ID1 = 1 ;

const uint8_t DXL_ID2 = 2 ;

const uint8_t DXL_ID3 = 3 ;

const uint8_t DXL_ID4 = 4 ;

const uint8_t DXL_ID5 = 5 ;

const uint8_t DXL_ID6 = 6 ;

const uint8_t DXL_ID7 = 7 ;

const uint8_t DXL_ID8 = 8 ;

const uint8_t DXL_ID9 = 9 ;

const uint8_t DXL_ID10 = 10 ;

const uint8_t DXL_ID11 = 11 ;

const uint8_t DXL_ID12 = 12 ;

const uint8_t DXL_ID13 = 13 ;

const uint8_t DXL_ID14 = 14 ;

const uint8_t DXL_ID15 = 15 ;

const uint8_t DXL_ID16 = 16 ;

const float DXL_PROTOCOL_VERSION = 2.0;

const uint8_t GP_DXL_CNT = 16; // nombre de DXL utilisés en mode Contrôle de position

const uint8_t GP_DXL_ID_LIST[GP_DXL_CNT] = {1,2,3,4,5,6,7,8,9,10,11,12,13,14,15,16}; //ID de servo définis en mode Contrôle de position

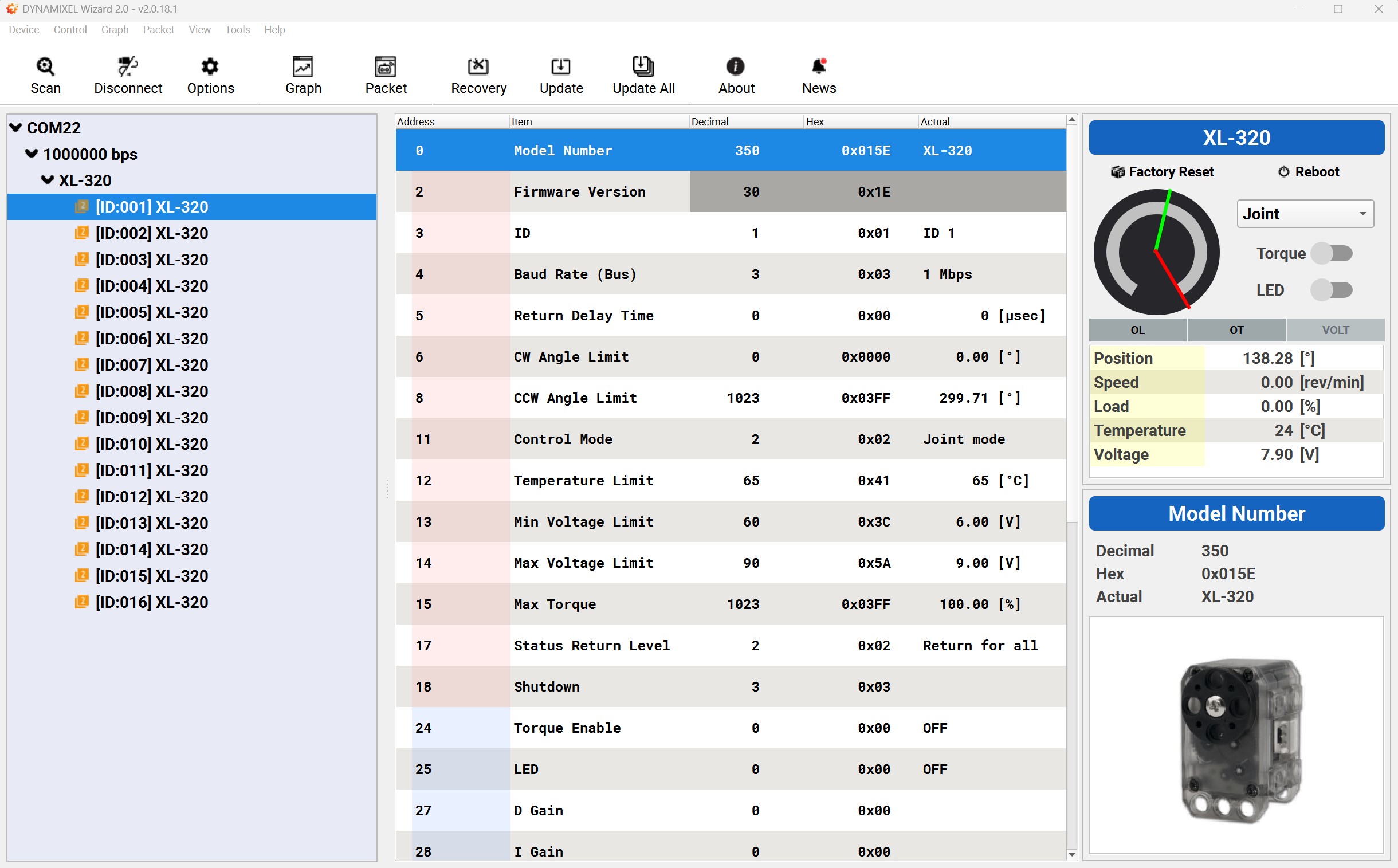

const uint16_t ADDR_X_PRESENT_POSITION = 37; // (XL-320)

const uint16_t LEN_X_PRESENT_POSITION = 2 ; // (XL-320)

const uint16_t ADDR_X_GOAL_POSITION = 30; // (XL-320)

const uint16_t LEN_X_GOAL_POSITION = 2; // (XL-320)

const uint16_t ADDR_X_MOVING_SPEED= 32; // (XL-320) adress 32 byt 2 0-2047

const uint16_t LEN_X_MOVING_SPEED= 2; // (XL-320)

const uint16_t ADDR_X_TORQUE_ENABLE= 24; // (XL-320) TORQUE_ENABLE adress 24 0 off 1 on

const uint16_t LEN_X_TORQUE_ENABLE= 1;

const uint8_t CONTROL_MODE = 2; // for XL320 adress 11 byt 1 mode 2 joint

Dynamixel2Arduino dxl_mini(DXL_SERIAL);

ParamForSyncWriteInst_t GP_sync_write_param; // Parameters structure for SW GP packet

ParamForSyncReadInst_t GP_sync_read_param; // Parameters structure for SR GP packet

RecvInfoFromStatusInst_t GP_read_result; // Structure for results of SR PP command

uint8_t dxl_error = 0; // Dynamixel error

int32_t dxl_present_position[GP_DXL_CNT] = { 0 }; // Tableau de position actuelle

int32_t dxl_goal_position[GP_DXL_CNT] = { 0 }; // Tableau de position d’objectif

bool read_present_positions_OK = false;

// Section MOUVEMENT

int _STEP_TIME_0 = millis();

int _STEP_TIME_1 = millis();

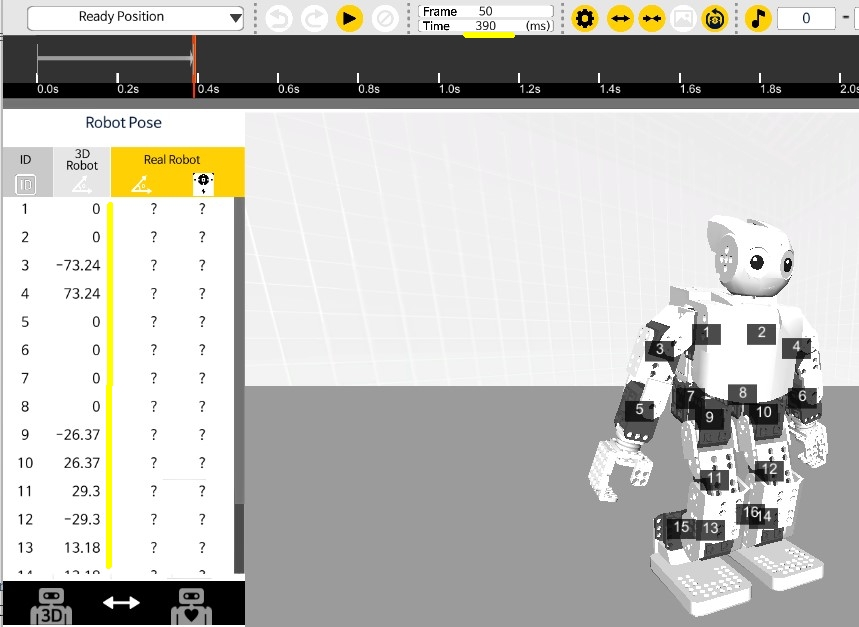

int _pose_init[17] ={390, 0, 0, -73.24, 73.24, 0, 0, 0, 0, -26.37, 26.37, 29.3, -29.3, 13.18, -13.18, 0, 0};

int salut_main [6][17] = { {100,-0.29, -150 ,-73.54 ,72.36, -0.29, 0.59 ,-0.29 ,-0.29, -26.66, 26.07 ,29, -29.59, 12.89, -13.48, -0.29, -0.29},

{0,-0.29 ,-149.71, -73.54, 51.27, -0.29, -33.69, -0.29, -0.29 ,-26.66, 26.07, 29 ,-29.59, 12.89, -13.48 ,-0.29 ,-0.29},

{0,-0.29 ,-150, -73.54, 91.7, -0.29, 32.81, -0.29 ,-0.29 ,-26.66 ,26.07 ,29 ,-29.59, 12.89, -13.48, -0.29, -0.29},

{0,-0.29 ,-149.71, -73.54, 51.27, -0.29, -33.69 ,-0.29, -0.29, -26.66 ,26.07 ,29 ,-29.59, 12.89, -13.48, -0.29, -0.29},

{0,-0.29 ,-150, -73.54, 91.7, -0.29, 32.81, -0.29, -0.29, -26.66, 26.07, 29 ,-29.59 ,12.89 ,-13.48, -0.29 ,-0.29},

{0,0 ,0 ,-73.24 ,73.24 ,0, 0, 0, 0 ,-26.37, 26.37, 29.3 ,-29.3 ,13.18 ,-13.18 ,0 ,0 } };

/*int salut_2 [6][17] = { {_STEP_TIME_1,-22.27 ,-44.24, -73.24, 73.24, 0, 0, 0, 0, -26.37, 26.07, 29.3, -29.3, 13.18, -13.48, 0, 0, },

{_STEP_TIME_1,-22.27,-44.24, -62.99, 92.58, -71.78, 58.59, 0, 0, -26.37, 26.07, 29.3, -29.3, 13.18, -13.48, 0, 0 },

{_STEP_TIME_1,-22.27, -69.73, -62.99, 92.58, -71.78, 58.59, 0, 0, -79.39, 82.91, 29.3, -29.3, -10.25, 10.55, 0, 0},

{_STEP_TIME_1,-22.27,-69.73, -62.99, 92.58, -71.78, 58.59, 0, 0, -79.39, 82.91, 29.3, -29.3, -10.25, 10.55, 0, 0},

{_STEP_TIME_1,-22.27, -44.24, -73.24, 73.24, 0, 0, 0, 0, -26.37, 26.07, 29.3, -29.3, 13.18, -13.48, 0, 0},

{_STEP_TIME_1,0, 0, -73.24, 73.24, 0, 0, 0, 0, -26.37, 26.37, 29.3, -29.3, 13.18, -13.18, 0, 0 } }; */

// ********** Function prototypes Prototypes de fonctions

int CalcAngle2Raw(int angle);

//bool check_motion();

int GP_time = _pose_init[0]; //c’est-à-dire _STEP_TIME_0

int CalcAngle2Raw(int angle)

{

return (int)(round((angle * 1023.0 / 300.0 + 512.0)));// return (int)(round((angle * 1023.0 / 300.0 + 512.0)));XL 320

} // fin de CalcAngle2Raw (angle int)

//**** Cet espace de noms est requis pour utiliser les noms d’éléments de la table de contrôle

using namespace ControlTableItem;

void setup()

{

int goal_position_raw = 0; // raw valeur brute de la position de l’objectif DXL

Serial.begin(115200);

while(!Serial); // attendez que l’opérateur ouvre Serial Monitor

//****** Configuration des Dynamixels pour mini ***pour XL320

dxl_mini.begin(1000000);

dxl_mini.setPortProtocolVersion(DXL_PROTOCOL_VERSION);

dxl_mini.scan();

Serial.println("Fin de la numérisation des DXL du robot ");

// Préparation du paquet GP SW

GP_sync_write_param.addr = ADDR_X_GOAL_POSITION;

GP_sync_write_param.length = LEN_X_GOAL_POSITION;

GP_sync_write_param.id_count = GP_DXL_CNT;

for(int i = 0; i < GP_DXL_CNT; i++){

GP_sync_write_param.xel[i].id = GP_DXL_ID_LIST[i];

}

Serial.println(“Fin de la préparation du paquet GP SW”);

// Préparation du paquet GP SR

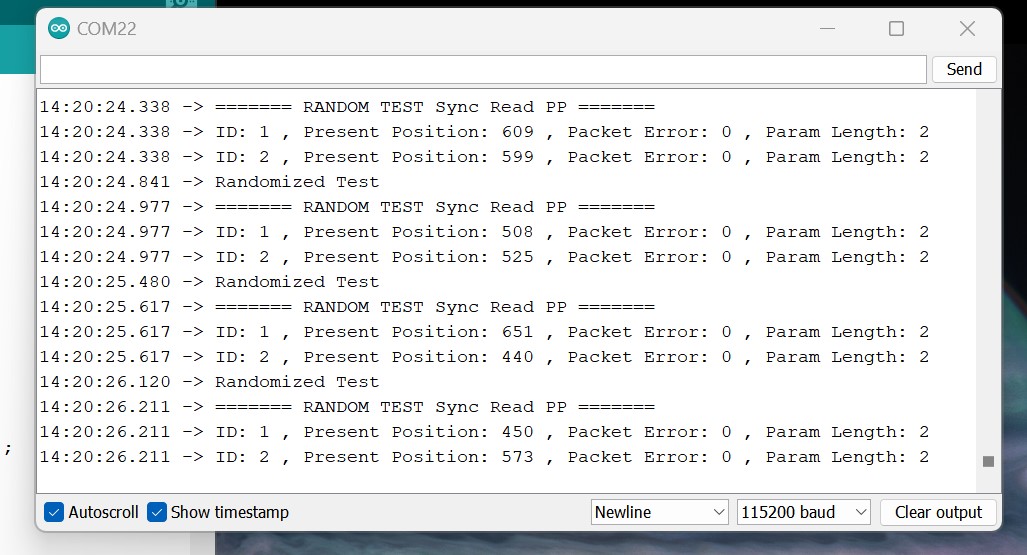

GP_sync_read_param.addr = ADDR_X_PRESENT_POSITION; // Present Position of DYNAMIXEL-X series

GP_sync_read_param.length = LEN_X_PRESENT_POSITION;

GP_sync_read_param.id_count = GP_DXL_CNT; // Number of servos in Position Control Mode

for(int i = 0; i < GP_DXL_CNT; i++){

GP_sync_read_param.xel[i].id = GP_DXL_ID_LIST[i];

}

Serial.println(“Fin de la préparation du paquet GP SR”);

// Configuration des servos GP dans la zone EEPROM : mode contrôle contrôle de position

// et dans la zone RAM : accélération du profil, vitesse du profil

for(int i = 0; i < GP_DXL_CNT; i++){

dxl_mini.torqueOff(GP_DXL_ID_LIST[i]); // Torque OFF

//dxl_mini.writeControlTableItem( GP_DXL_ID_LIST[i],CONTROL_MODE); //

dxl_mini.setOperatingMode(GP_DXL_ID_LIST[i], OP_POSITION); // Position Control

dxl_mini.torqueOn(GP_DXL_ID_LIST[i]); // Torque ON

delay(100); // attendez un peu avant de travailler dans la zone RAM

}

Serial.println(“Fin de la configuration des servos GP”);

delay(3000);

Serial.println(“Mettre le robot dans la pose initiale”);

// Réglez le robot sur la pose _ via SyncWrite

// Allouez la valeur brute de chaque position d’objectif dans le paquet GP SW, un DXL à la fois en utilisant les valeurs du tableau global _[1] à _[17]

for (int i = 0; i < GP_DXL_CNT; i++) // DXL 1 à 16

{

goal_position_raw = CalcAngle2Raw(_pose_init[i+1]); // convertir l’angle de mouvement en position d’objectif brute [0-4096], _[0] n’est pas utilisé ici

memcpy(GP_sync_write_param.xel[i].data, &goal_position_raw, sizeof(goal_position_raw));

}

dxl_mini.syncWrite(GP_sync_write_param); // send GP SW Packet

delay(3000);

// fin de l’installation() et de la pose initiale"

Serial.println(“jouer mouvement bras”);

for (int frame_no = 0; frame_no < 6; frame_no++) // 4 images de mouvement ont été définies pour le mouvement vers l’avant

{

GP_time = (int)(round(salut_main[frame_no][0] )); //c’est-à-dire STEP TIME 1 modifié avec le facteur de vitesse

//(int)(round(forward[frame_no][0] )); //c’est-à-dire STEP TIME 1 modifié avec le facteur de vitesse

for (int i = 0; i < GP_DXL_CNT; i++) // Définition des valeurs GP brutes pour les Walking DXL 1 à 8

{

goal_position_raw = (CalcAngle2Raw(salut_main[frame_no][i + 1]) ); //convertir l'angle de mouvement avec Adj Offset en Raw GP

memcpy(GP_sync_write_param.xel[i].data, &goal_position_raw, sizeof(goal_position_raw));

}

if (dxl_mini.syncWrite(GP_sync_write_param) == false) // envoyer le paquet GP SW

{

Serial.println("Sfin mouvement");

}

delay(400); // en attendant que chaque image clé soit jouée en ms

} // fin de pour (numéro de trame)

} // fin du mouvement bras

void loop()

// Réinitialisation du robot à la pose d’initialisation

{

int GP_time = _pose_init[0]; //c’est-à-dire _STEP_TIME_0

int goal_position_raw = 0; // valeur brute de la position de l’objectif DXL

for (int i = 0; i < GP_DXL_CNT; i++) // Définir GP pour les DXL 1 à 16

{

goal_position_raw = CalcAngle2Raw(pose_init[i+1]); //convertir l’angle de mouvement en position d’objectif brute [0-1023]

memcpy(GP_sync_write_param.xel[i].data, &goal_position_raw, sizeof(goal_position_raw));

}

if (dxl_mini.syncWrite(GP_sync_write_param) == false) // envoyer le paquet GP SW si faux

{

Serial.println(“Échec du logiciel”); //Échec du logiciel pour SW_TC()

// return 0;

}

delay(3000); // en attente de la réinitialisation de la pose pour jouer en ms

} >`